- Understanding the Problem Scope

- Setting Up the Simulation in Ansys Fluent

- 1. Geometry Creation

- 2. Mesh Generation

- 3. Solver Selection and Configuration

- Simulating Key Variables

- 1. Effect of Bubble Radius

- 2. Single Bubble vs. Cluster of Bubbles

- 3. Effect of Varying Ultrasound Frequencies

- Influence of Environmental Conditions

- 1. Bubble Near a Wall vs. Infinite Liquid

- 2. Effect of Transducer Distance

- Post-Processing and Results Interpretation

- Conclusion

Computational Fluid Dynamics (CFD) assignments involving bubble collapse under ultrasound exposure require a structured approach to ensure accuracy and reliability. These assignments, often complex and multi-faceted, demand a deep understanding of fluid mechanics, numerical modeling, and simulation techniques. Proper execution of these tasks ensures meaningful insights into bubble dynamics, making the learning process more effective. Such assignments, typically solved using Ansys Fluent, involve setting up models, defining boundary conditions, running simulations, and analyzing results. Each step plays a crucial role in ensuring the validity of the obtained results, and missing a critical parameter could lead to inaccurate findings. Additionally, CFD assignments can vary in complexity, from simple single-bubble studies to highly intricate simulations involving multiple interacting bubbles under different environmental conditions. Whether you're a student looking for CFD Assignment Help or an engineer striving to perfect your simulations, understanding and implementing these steps effectively can be the difference between a successful simulation and one riddled with errors. If you're new to simulation-based assignments, consulting a Solidworks Assignment Helper can provide valuable guidance to streamline your approach. This blog will guide you through solving these types of assignments step by step, using a problem framework similar to the one provided.

Understanding the Problem Scope

Before diving into Ansys Fluent, it's crucial to understand the assignment's requirements. In this case, we are dealing with the simulation of a gaseous bubble collapsing under ultrasound exposure, with multiple influencing factors such as:

- Bubble radius and how its size affects collapse dynamics.

- Varying ultrasound frequencies and their influence on bubble behavior.

- Effect of wall proximity and how solid boundaries alter collapse patterns.

- Single vs. cluster bubbles to observe how neighboring bubbles impact each other.

- Distance of the ultrasound transducer to the bubble, which can change the effectiveness of ultrasonic waves.

- Different surrounding pressures, affecting the overall dynamics of bubble collapse.

Understanding these variables is the first step in developing a computational model that accurately captures real-world phenomena.

Setting Up the Simulation in Ansys Fluent

1. Geometry Creation

- Defining the Bubble Geometry

- Fluid Domain Selection

- Boundary Conditions

- Bubble Surface: Free boundary condition to allow expansion and collapse dynamically.

- Outer Domain: Pressure far-field boundary to mimic an infinite liquid surrounding the bubble.

The first step in setting up your simulation is to create the bubble’s geometry in Ansys. Typically, the bubble is assumed to be a perfect sphere with an initial radius of 10μm. However, you may need to adjust this depending on the assignment specifications.

The bubble is submerged in water. Thus, the computational domain should be a fluid region with water as the medium. The size of the domain should be large enough to prevent boundary effects from influencing the results. A typical approach is to use a domain size that is at least 10 times the bubble radius.

2. Mesh Generation

- Importance of High-Quality Meshing

The accuracy of the simulation depends significantly on mesh quality. A structured mesh with refined grid elements near the bubble ensures correct pressure and velocity gradient calculations. It is recommended to use adaptive mesh refinement (AMR) to refine the mesh dynamically in areas with strong gradients.

- Running Mesh Quality Tests

After meshing, run quality tests such as aspect ratio, skewness, and orthogonality checks to ensure simulation stability. A good quality mesh will enhance convergence and reduce numerical errors.

3. Solver Selection and Configuration

- Choosing the Right Solver

- DNS (Direct Numerical Simulation) is highly accurate but computationally expensive.

- RANS (Reynolds-Averaged Navier-Stokes) provides an approximation that reduces computational costs.

- Defining Governing Equations

- The Rayleigh-Plesset equation describes bubble dynamics, which is crucial for understanding the growth and collapse phases.

- The Navier-Stokes equations govern fluid motion and interaction with the bubble.

- The Continuity and Momentum equations ensure mass and energy conservation within the system.

- Setting Initial and Boundary Conditions

- Initial Pressure inside the Bubble: Uniform pressure assumption.

- Fluid Properties: Water density and viscosity values need to be correctly defined.

- Turbulence Model: Use appropriate models depending on the chosen solver.

For bubble collapse problems, the solver choice depends on computational resources and accuracy requirements:

Simulating Key Variables

1. Effect of Bubble Radius

- Defining Different Bubble Sizes

- Impact on Collapse Time and Pressure

- Smaller bubbles collapse faster and generate higher pressures.

- Larger bubbles take more time to collapse but might generate stronger shockwaves due to increased stored energy.

- Effect of Surrounding Pressure

To analyze the effect of bubble size, simulations should be conducted for different radii (e.g., 0.01mm and 0.02mm). This helps in understanding how collapse time and maximum pressure depend on initial bubble size.

The same tests should be performed under various pressures, including -0.4kPa, 10.7kPa, 0.8kPa, and 0kPa to observe pressure-dependent behavior.

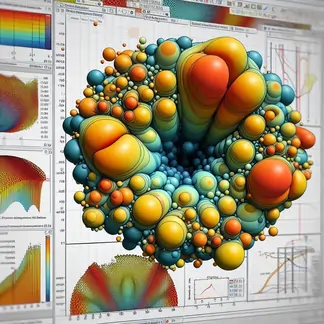

2. Single Bubble vs. Cluster of Bubbles

- Defining a Cluster

- Interaction Between Bubbles

- A single bubble collapses symmetrically.

- In a cluster, pressure waves from one bubble influence the collapse of others, leading to complex asymmetric behaviors.

Instead of a single bubble, simulate three closely packed bubbles to study bubble-bubble interaction and how it affects the collapse dynamics.

3. Effect of Varying Ultrasound Frequencies

- Testing Different Frequencies

- Observing Bubble Response

- Low-frequency ultrasound results in larger oscillations.

- Higher frequencies lead to faster collapse and higher pressures.

Simulations should be conducted for 0.5MHz, 1.5MHz, and 3MHz to determine how bubble oscillations change with ultrasound intensity.

Influence of Environmental Conditions

1. Bubble Near a Wall vs. Infinite Liquid

- Wall Effect on Bubble Collapse

- In free space, the bubble collapses symmetrically.

- Near a solid wall, the collapse becomes asymmetric, forming a high-speed jet directed toward the wall.

- Pressure Variations Due to the Wall

- A wall intensifies pressure buildup.

- The jet formed can cause erosion effects on the surface, which is an important consideration in industrial applications.

2. Effect of Transducer Distance

- Varying Transducer Position

- Identifying the Optimal Position

- A closer transducer results in stronger bubble oscillations.

- A farther transducer leads to weaker but more diffused effects.

Place the ultrasound source at three different distances and observe how it influences the pressure field around the bubble.

Post-Processing and Results Interpretation

- Extracting Key Data

- Flow pattern images (color maps)

- Pressure gradients

- Bubble collapse vs. time graphs

- Pressure oscillations over time

- Validating Results with Literature

- Reporting and Documentation

- Include annotated screenshots of graphs.

- Clearly label axes and highlight critical observations.

After running the simulations, analyze the results by generating:

Compare simulation results with theoretical studies to ensure accuracy.

Conclusion

By following a structured approach to CFD simulations on bubble collapse using Ansys Fluent, students can develop an in-depth understanding of complex fluid behaviors. Ensuring high-quality mesh, selecting the right solver, and validating results with literature enhances simulation reliability, making it a valuable learning experience in computational fluid dynamics.

.webp)