- Understanding the Bottleneck: What Makes Bottle Cap Modeling Challenging?

- Step 1: Start with a Clear Plan and Base Sketch

- Step 2: Extrude the Base Cylinder

- Step 3: Apply Edge Fillets for Stronger Design and Smooth Transitions

- Step 4: Shell the Model for Realistic Hollow Caps

- Step 5: Create Reference Planes and Secondary Features

- Step 6: Adding Key Details with Extrusions and Cuts

- Step 7: Final View and Validation

- Common Pitfalls and How SolidWorks Assignment Help Addresses Them

- Tips for Efficient and Accurate Assignment Completion

- Final Thoughts

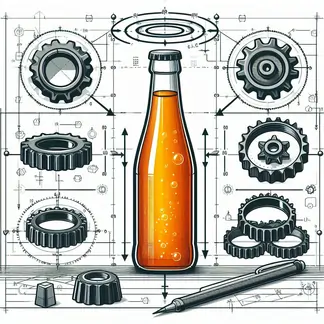

SolidWorks assignments are an integral part of engineering coursework, challenging students to develop parametric modeling, feature management, and design precision skills that translate directly to real-world applications. Among the common part modeling tasks, designing a bottle cap offers a great learning opportunity to apply a blend of basic and advanced SolidWorks features—skills essential for any budding engineer. This includes mastering tools like the revolved features, which many find critical, thus making SolidWorks Revolving Features Assignment Help highly sought after by students aiming to perfect these techniques. While this blog does not solve the specific attached assignment alone, it provides a detailed framework and workflow strategy closely aligned with assignments of this nature, offering practical insights and actionable tips that students can utilize with confidence and efficiency. Whether tackling this as a standalone assignment or part of a broader course, many students often look for professional assistance through services like Do My Solidworks Project to clarify concepts, troubleshoot problems, and optimize their modeling quality. This guide carefully walks through all essential stages—from sketching the base profile to applying fillets, shell features, and reference planes—emulating the key steps critical for successful bottle cap modeling and helping students build strong CAD skills for future projects.

Understanding the Bottleneck: What Makes Bottle Cap Modeling Challenging?

Although a bottle cap might seem like a simple part, it encapsulates various nuanced modeling challenges:

- Applying precise dimensional controls for fitting and sealing.

- Creating complex shapes using operations like extrusions “up to surface” that require an understanding of reference geometry.

- Using shell features to hollow out volumes accurately.

- Effectively applying fillets for aesthetic and functional edge finishing.

Assignments often require handling a combination of these elements, which builds a solid foundation for complex part and assembly modeling.

Step 1: Start with a Clear Plan and Base Sketch

Before jumping into SolidWorks, capture the assignment’s key requirements. Identify critical dimensions such as diameter, height, wall thickness, fillet radii, and any peculiar design features like ridges or grooves specific to the cap.

Open a new part in SolidWorks and select the Top Plane to start creating your base sketch:

- Use the Circle tool to draw the cap's outer diameter.

- Add precise Smart Dimensions for the diameter (e.g., 1.0 inch).

- This step establishes the foundation, so full sketch definition is important to avoid future errors.

This stage mirrors many bottle cap assignments in SolidWorks courses. It demonstrates the principle that every complex part is just a build-up of simple, well-defined sketches.

Step 2: Extrude the Base Cylinder

Apply the Extruded Boss/Base feature to convert your 2D circle into a 3D form:

- Set the extrusion depth based on design notes or assignment instructions (e.g., 0.5 inches).

- Choose appropriate direction (blind extrude is common).

- Use draft options if required to taper the walls outward for mold release considerations.

Extruding the cylinder provides the volumetric base that subsequent features rely on. Common mistakes here include incorrect extrusion depth or missing draft angles affecting manufacturability.

Step 3: Apply Edge Fillets for Stronger Design and Smooth Transitions

Select the top face or edges of the cylinder and apply a Fillet (e.g., radius 0.1 inch):

- Use Multiple radius fillets for varied edge smoothness.

- Check Tangent Propagation to ensure a natural blend into adjoining faces.

Fillets are crucial because sharp edges reduce product durability and can cause stress concentration points that may lead to failures.

Step 4: Shell the Model for Realistic Hollow Caps

Next, the bottle cap must have a hollow interior:

- Use SolidWorks Shell feature.

- Select the bottom face to remove and shell the walls inward by a specific thickness (e.g., 0.05 inches).

- This step mimics the thinning of the bottle cap’s material, important for fitting and cost management.

Using the shell command correctly is a recurring theme in many assignments, demonstrating how negative features work and how internal volumes are manipulated.

Step 5: Create Reference Planes and Secondary Features

Often, the bottle cap has design details that are not on the base extrusion face. You’ll need to:

- Insert a reference plane offset from the Front Plane.

- Sketch secondary shapes like ridges, slot features, or bosses on this new plane.

- Use Up To Surface extrusions to integrate these features smoothly with the existing main body.

This technique is commonly tested in assignments to evaluate how students manage complex geometry using reference features.

Step 6: Adding Key Details with Extrusions and Cuts

Many bottle caps feature additional details:

- Use Rectangles or other sketches on the reference plane.

- Apply Extruded Boss/Base with the Up To Surface option, merging the result with the original solid.

- Apply Fillet on side edges to round the features.

- Use Extruded Cut operations to create holes, grooves, or locking mechanisms.

Precision in placement and correct selection of the surface or face during these operations often distinguishes a great CAD model from a subpar one.

Step 7: Final View and Validation

Once the features are complete:

- Rotate the part to an isometric view and review all dimensions.

- Use Measure tools to cross-check key distances.

- Ensure the shell wall thickness is uniform and that fillets present smooth transitions.

- Validate if your model matches the assignment’s functional and aesthetic requirements.

Common Pitfalls and How SolidWorks Assignment Help Addresses Them

Even seasoned students face challenges such as:

- Misdefined sketches or under-dimensioned profiles.

- Incorrect use of reference planes leading to misaligned features.

- Shelling errors generating unusable or incomplete models.

- Difficulty managing complex fillets and draft angles.

Using expert solidworks assignment help ensures students overcome these issues efficiently. Professionals guide students through stepwise troubleshooting and help optimize modeling best practices.

Tips for Efficient and Accurate Assignment Completion

- Always fully define sketches. Undefined sketches cause cascading errors.

- Respect relation constraints to allow dynamic updating.

- Use reference planes wisely to avoid clutter and confusion.

- Work incrementally, saving versions to revert when needed.

- Leverage SolidWorks tutorials and forums for tricky features.

- Apply consistent units and dimension standards to avoid mismatch errors.

Final Thoughts

Modeling a bottle cap in SolidWorks symbolizes the bridge from basic parts to professional industrial design. By following the structured approach outlined above—centering around sketching, extrusion, filleting, shelling, and reference geometry mastery—students can confidently solve similar assignments while embracing the precision that engineering demands.

For personalized support, troubleshooting, and advanced tips, solidworks assignment help services offer tailored assistance that elevates both assignment quality and learning outcomes.