- Understanding the Assignment: What It Really Involves

- Research and Concept Sketching

- Setting Up Your SolidWorks Environment

- Starting the Car Body: Solid and Surface Modeling Techniques

- Building the Base Shape

- Creating Surfaces

- Converting to Solid

- Designing Car Components and Assemblies

- Wheels and Rims

- Headlights and Grilles

- Doors and Windows

- Refinement and Detailing

- Preparing the Model for 3D Printing

- Checking Printability

- Exporting to STL

- Choosing Material

- Orientation and Support

- Post-Processing

- Common Mistakes Students Make (and How to Avoid Them)

- Rendering and Presentation

- Integrating Engineering Principles: Aerodynamics and Efficiency

- Documentation and Report Preparation

- Learning Outcome: Why Assignments Like These Matter

- When to Seek Professional Guidance

- Final Thoughts

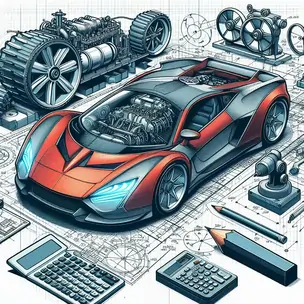

Designing concept cars using SolidWorks and 3D printing is one of the most creative and technically engaging challenges that university students encounter today. These assignments go far beyond simple 3D modeling — they combine innovation, engineering precision, and manufacturing awareness into a single comprehensive project. Students are expected to visualize futuristic designs, convert their ideas into parametric SolidWorks models, and finally prepare them for additive manufacturing using 3D printing technologies. If you’re seeking SolidWorks 3D Printing assignment help or need solidworks assignment help for detailed modeling or printing tasks, understanding the professional workflow behind concept car development can transform your results. This blog walks you through the entire process — from conceptual sketches and surface modeling to creating assemblies, refining geometries, and ensuring your design is fully optimized for 3D printing. Whether your goal is to complete a university project, enhance your portfolio, or simply learn how industry experts create next-generation automotive prototypes, this guide will help you think, design, and execute like a professional engineer.

Understanding the Assignment: What It Really Involves

University assignments involving SolidWorks and 3D printing typically ask students to design a futuristic concept car, prototype component, or assembly using parametric modeling, surfacing, and 3D print-ready features.

These tasks are not just about drawing shapes — they test your ability to:

- Combine creativity with engineering precision

- Apply design-for-manufacturing (DFM) principles

- Use surface modeling tools for aesthetics

- Optimize models for 3D printing feasibility

Before you start, carefully read the requirements. Typical university assignments outline:

- Design objectives (aerodynamic form, ergonomic shape, or futuristic look)

- Tools to be used (SolidWorks features like lofts, sweeps, surface blends)

- Constraints (size, material, printing method, or tolerance)

- Expected deliverables (3D model, exploded views, STL files, and renderings)

Understanding this foundation saves time and ensures you build your model the right way.

Research and Concept Sketching

Every great 3D model starts with a clear concept. For car-based SolidWorks projects, inspiration often comes from existing concept cars, aerodynamics, or electric vehicle prototypes.

Steps before opening SolidWorks:

- Collect references – Study the contours, proportions, and styling trends of concept cars from companies like BMW, Tesla, or Audi.

- Sketch basic profiles – Draw front, top, and side views on paper or digitally.

- Define proportions – Wheelbase, height, body curvature, and symmetry must be realistic.

- Visualize functionality – Think about how doors open, wheels rotate, and components fit.

This creative stage helps guide your modeling path and ensures your car design feels intentional rather than random.

Setting Up Your SolidWorks Environment

Before you begin modeling, create a clean, organized project environment:

- Set up units (usually millimeters for automotive design).

- Configure the front, top, and right planes according to your sketches.

- Save your file with versioning (e.g., “ConceptCar_V1.SLDPRT”) to track progress.

- Enable RealView Graphics for realistic visualization.

Next, import your sketches as background images to serve as underlays for precise modeling. This is a professional technique used in automotive design studios.

Starting the Car Body: Solid and Surface Modeling Techniques

The main challenge in concept car assignments is building a smooth, organic body. In SolidWorks, you’ll use a mix of solid modeling for structural elements and surface modeling for the sleek body curves.

Building the Base Shape

- Begin with a centerline sketch to ensure symmetry.

- Use splines instead of straight lines for natural car contours.

- Employ Lofted Boss/Base or Boundary Surface features to blend different sections smoothly.

Creating Surfaces

Switch to the Surface tab:

- Use Surface Loft, Surface Fill, and Surface Knit to develop the car’s shell.

- Combine smaller surfaces into one using Knit Surface and check for gaps with Surface Evaluation > Zebra Stripes for continuity.

Converting to Solid

Once your body is complete:

- Use Thicken to create a solid wall for printing.

- Ensure a minimum wall thickness of 1.2–2 mm (depending on printer and material).

This hybrid workflow — solids for structure and surfaces for form — gives you both beauty and precision.

Designing Car Components and Assemblies

After the body, your assignment might require modeling functional parts like wheels, lights, or interior components.

Wheels and Rims

- Sketch circular profiles on the Front Plane.

- Use Revolve Boss/Base for tire and rim shapes.

- Add patterns for spokes using Circular Pattern.

Headlights and Grilles

- Use Extruded Cut or Loft Cut for light slots.

- Create transparent materials for lenses via Appearance settings.

Doors and Windows

- Draw part boundaries on the main surface.

- Use Split Line and Surface Trim to isolate and modify door regions.

- Keep separate parts for assembly flexibility.

Once you’ve modeled all components, assemble them in a new Assembly file:

- Use Mate constraints (coincident, concentric, parallel) to position parts accurately.

- Ensure every component fits without interference using Interference Detection.

Refinement and Detailing

Concept car design isn’t just about large forms — it’s about details that make it realistic. To elevate your model:

- Add fillets and chamfers for soft transitions.

- Apply curvature analysis to eliminate uneven surfaces.

- Use Split Body for defining multi-material regions (e.g., glass vs metal).

- Label internal features (engine bay, dashboard, etc.) for clarity in your report.

Before exporting, perform a Design Study to test different dimensions or configurations, as professors often grade based on flexibility and creativity.

Preparing the Model for 3D Printing

Once your model is complete, the next step is to make it 3D-print ready. Many students overlook this phase, but it’s vital in assignments that involve prototyping.

Checking Printability

Go to Tools → Evaluate → Check to ensure:

- No open surfaces (the model must be watertight).

- Wall thickness meets printer specifications.

- No small, unprintable features (like tiny fillets).

Exporting to STL

- Choose File → Save As → STL.

- Use a Fine resolution for smoother curves.

- Ensure “Output as Binary” is selected to reduce file size.

Choosing Material

For car models:

- PLA: Best for simple visual prototypes.

- ABS: Stronger and smoother finish.

- Resin: High precision for display models.

Orientation and Support

In your slicing software (Cura, PrusaSlicer, etc.):

- Place the car body flat on the build plate.

- Use minimal supports to avoid marks on visible areas.

- Adjust infill density (10–20%) for balance between weight and strength.

Post-Processing

After printing, smooth the surface using:

- Fine-grit sandpaper (200–400 grit)

- Primer coating and spray paint

- Optional clear coat for glossy finish

This workflow ensures your SolidWorks model transitions seamlessly from screen to physical reality — an essential skill for modern engineers.

Common Mistakes Students Make (and How to Avoid Them)

Even good models can lose marks due to simple errors. Here are the top mistakes students should watch for:

- Ignoring scale – Always confirm the overall car size matches assignment specifications.

- Overcomplicating geometry – Simplicity is key for both grading and printing success.

- Skipping feature hierarchy – Misusing parent-child features leads to rebuild errors.

- Forgetting symmetry – Always use Mirror features for consistent halves.

- Exporting without repair – Unhealed surfaces or holes cause STL errors.

- Wrong tolerances – Overly tight fits may prevent part assembly post-print.

- Poor documentation – Include screenshots, dimension tables, and renderings in your submission.

By following a structured approach, you demonstrate both design and manufacturing understanding — exactly what examiners look for.

Rendering and Presentation

A great model deserves an impressive presentation. Use SolidWorks Visualize or PhotoView 360 to render your concept car:

- Choose realistic materials (metallic paints, rubber, glass).

- Set up HDR lighting environments for reflection realism.

- Use exploded views to showcase internal assemblies.

- Include annotation callouts and dimensioned drawings in your report.

For students, presentation can earn bonus marks — it reflects attention to detail and professional design ethics.

Integrating Engineering Principles: Aerodynamics and Efficiency

Beyond aesthetics, concept car design should reflect engineering sense. When your assignment includes an analytical component:

- Use Flow Simulation in SolidWorks to analyze air resistance.

- Optimize the front and rear curvature for minimal drag.

- Test downforce balance using virtual wind tunnel simulations.

- Evaluate weight distribution using Mass Properties.

Such analyses show your understanding of both design and function — a key factor in distinction-level grading.

Documentation and Report Preparation

Your SolidWorks assignment isn’t complete without a clear report. Include the following:

- Introduction – Project aim and design concept.

- Design methodology – Sketching, modeling, surfacing, and assembly process.

- Feature list – Key SolidWorks tools used and why.

- 3D printing preparation – Material selection, printer setup, STL generation.

- Results – Rendered images and print photos (if applicable).

- Discussion – Lessons learned or design challenges.

This structure ensures you present a professional-grade submission aligned with university expectations.

Learning Outcome: Why Assignments Like These Matter

Assignments that combine SolidWorks and 3D printing are not just academic exercises — they’re training grounds for real-world design thinking.

These projects teach students to:

- Convert ideas into tangible prototypes.

- Integrate aesthetics, physics, and manufacturability.

- Understand how CAD data translates into 3D-printed output.

- Build portfolios that impress recruiters in product design, mechanical engineering, and automotive sectors.

Completing such assignments successfully builds both technical confidence and creative problem-solving ability.

When to Seek Professional Guidance

Sometimes, despite best efforts, students struggle with complex surface modeling, STL errors, or printing compatibility. That’s when expert guidance can make a difference.

Professional services like SolidWorks 3D Printing assignment help offer step-by-step mentoring, file corrections, and simulation advice. Similarly, if your university project involves assemblies, motion analysis, or rendering, getting solidworks homework help ensures your design meets both academic and professional standards.

Learning from guided solutions helps you understand advanced SolidWorks workflows while maintaining academic integrity.

Final Thoughts

Designing a concept car using SolidWorks and 3D printing isn’t just about completing an assignment — it’s about understanding the future of engineering design. As industries shift toward additive manufacturing, the ability to model print-ready, aesthetically pleasing, and structurally sound components becomes a core skill.

By following the structured process discussed in this blog — from concept ideation and modeling to assembly and printing — university students can not only ace their assignments but also prepare themselves for professional design challenges ahead.

So next time you receive a SolidWorks project similar to designing a concept car, remember: start with creativity, work with precision, and always finish with manufacturability in mind.