- Understanding Multibody Parts and Assemblies

- Multibody Parts

- Assemblies

- When to Use Each Approach?

- Working with Saving Bodies Functions

- Save Bodies Feature

- Steps to Save Bodies

- Case Study: Clamp

- Benefits of Saving Bodies

- Splitting Parts into Multiple Bodies

- Split Feature

- Steps to Use Split Feature

- Case Study: Handle

- Modeling for Rapid Tooling

- Automating Assemblies and Working with Legacy Data

- Techniques for Automation

- Case Study: Using Split Part with Legacy Data

- Conclusion

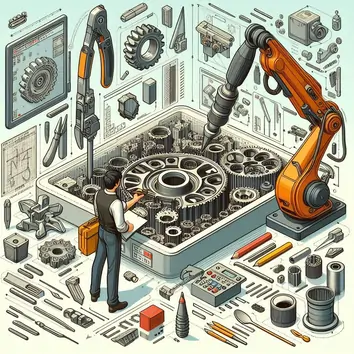

SolidWorks is an incredibly powerful tool for engineering design, offering advanced features that enhance productivity and efficiency when working on complex models. Whether you are a student tackling intricate assignments or an engineer handling large-scale industrial projects, mastering SolidWorks can provide a competitive edge. One of the most essential skills in SolidWorks is effectively managing solid bodies, which plays a crucial role in modeling, prototyping, and manufacturing. Understanding how to manipulate, split, and save solid bodies can streamline the design process, reduce errors, and optimize production workflows. This is particularly important when working with multibody parts and assemblies, where knowing when to use each approach can greatly impact the final product's performance and manufacturability. From splitting a part into multiple bodies to automating assemblies, these techniques are invaluable for anyone looking to refine their SolidWorks expertise. This blog will provide an in-depth exploration of key concepts related to saving solid bodies, the difference between multibody parts and assemblies, and real-world applications of these techniques. If you're struggling with a project and wondering, "Who can solve my SolidWorks assignment?", our SolidWorks assignment help service is here to provide expert guidance and ensure that your designs meet industry standards with precision and efficiency.

Understanding Multibody Parts and Assemblies

SolidWorks offers different approaches for handling multiple components within a single project. The two main methods are multibody parts and assemblies. Understanding their differences and applications is crucial for efficient design and manufacturing.

Multibody Parts

A multibody part is a single SolidWorks part file (.SLDPRT) containing multiple solid bodies that can be independently manipulated. This approach is useful for designing components that originate from a single piece of material, such as cast or machined parts.

Assemblies

An assembly consists of multiple part files combined within a SolidWorks assembly file (.SLDASM). Assemblies allow users to apply constraints and mates to simulate how components fit and interact in the real world.

When to Use Each Approach?

- Use a multibody part when designing a component that will later be separated into different parts, such as a mold or casting.

- Use an assembly when modeling a product made of distinct parts that need to move relative to each other.

Working with Saving Bodies Functions

SolidWorks provides multiple ways to extract and save bodies from a multibody part file. The Save Bodies function enables designers to convert solid bodies into separate part files while maintaining parametric links.

Save Bodies Feature

The Save Bodies feature allows users to extract individual bodies from a multibody part and store them as separate part files.

Steps to Save Bodies

- Open the multibody part in SolidWorks.

- Navigate to Insert > Features > Save Bodies.

- Select the bodies you wish to save as separate parts.

- Specify file names and locations for the new part files.

- Choose whether to create an assembly that includes all the saved parts.

- Click OK to finalize the operation.

Case Study: Clamp

A practical example of the Save Bodies function is designing a clamp. Initially, a single multibody part file is created with separate sections for the handle, jaws, and screw mechanism. By using the Save Bodies feature, these sections can be extracted as independent parts while preserving their relationships in an assembly.

Benefits of Saving Bodies

- Enables part separation for manufacturing.

- Maintains parametric relationships between parts.

- Improves flexibility in design modifications.

Splitting Parts into Multiple Bodies

Splitting a single part into multiple bodies is a valuable feature when working on complex designs. The Split feature in SolidWorks allows users to divide a model into separate solid bodies.

Split Feature

The Split feature enables users to cut a solid body into multiple independent parts, which can later be saved as separate part files.

Steps to Use Split Feature

- Open the part file.

- Navigate to Insert > Features > Split.

- Select the cutting plane or sketch to define the separation.

- Assign names to the resulting bodies.

- Save the split bodies as separate part files.

Case Study: Handle

Consider a handle design where the grip and mounting section need to be manufactured separately. Using the Split feature, the design can be divided into two solid bodies, allowing for separate material selection and processing.

Modeling for Rapid Tooling

When designing for rapid tooling, such as injection molds, it's essential to split parts into multiple bodies. This enables quick adjustments and separate manufacturing of mold components.

Key Considerations

- Design for manufacturability: Ensure that parts can be easily separated for mold production.

- Use of mold tools: Utilize SolidWorks’ mold tools for core and cavity design.

- Feature recognition: Identify undercuts, draft angles, and parting lines early in the design phase.

Automating Assemblies and Working with Legacy Data

Automating assemblies in SolidWorks helps streamline design processes and reduce repetitive tasks. Additionally, working with legacy data (older CAD models) often requires modifying existing models using tools like Split Part.

Techniques for Automation

- Configurations: Create different versions of an assembly within a single file.

- Design Tables: Use Excel-driven parameters to control multiple design variations.

- Macros and API: Automate repetitive tasks using SolidWorks’ built-in programming capabilities.

Case Study: Using Split Part with Legacy Data

A company has an old design for a machine component but needs to add additional mounting points. Instead of remodeling from the ground up, the Split Part tool allows engineers to break the existing design into editable sections, making modifications easier and faster.

Conclusion

Mastering saving solid bodies, multibody vs. assembly modeling, splitting parts, and automating assemblies is essential for efficient SolidWorks modeling. These tools enable engineers to create flexible and manufacturable designs, especially when working with complex projects. If you need assistance with your assignments involving these techniques, our SolidWorks assignment help service is here to provide expert guidance. Whether you’re struggling with part splitting, saving bodies, or automating assemblies, our team can help you achieve accurate and efficient results. So, if you find yourself asking, "Can someone solve my SolidWorks assignment?", reach out to us for professional support and high-quality solutions.